FRANKFURT, November 2025 – This month has been a landmark period for the global aerosol industry, with significant announcements highlighting a decisive shift towards carbon-neutral production, intelligent packaging, and the adoption of next-generation propellants. The industry's evolution is being shaped by regulatory pressures, consumer demand for eco-friendly products, and technological breakthroughs.

1. Breakthrough in Propellant Technology: BASF and Koura Unveil New Low-GWP Blend

A major technical hurdle has been cleared this November. Chemical giants BASF and Koura have jointly launched a novel propellant blend, trademarked "Solstice-Aero 550," designed as a near-drop-in replacement for HFC-152a in personal care aerosols.

Key Advantage: The blend boasts a Global Warming Potential (GWP) of under 10, a significant reduction from HFC-152a's GWP of 124, while maintaining comparable vapor pressure and solvency. This allows formulators to make the switch with minimal product re-engineering.

Industry Impact: With the EU F-gas regulation phase-down accelerating in 2026, this new blend provides a critical, high-performance pathway for brands to comply without sacrificing product quality. Several major deodorant and hair care brands are already in advanced testing phases.

2. S.C. Johnson & Son Launches "Clean-Fill" Aerosol Production Line

In a bold manufacturing move, S.C. Johnson & Son has announced the launch of its first "Clean-Fill" aerosol production facility in the Netherlands. The line is powered entirely by renewable energy and utilizes a proprietary "dry-fill" technology that significantly reduces propellant fugitive emissions during the filling process.

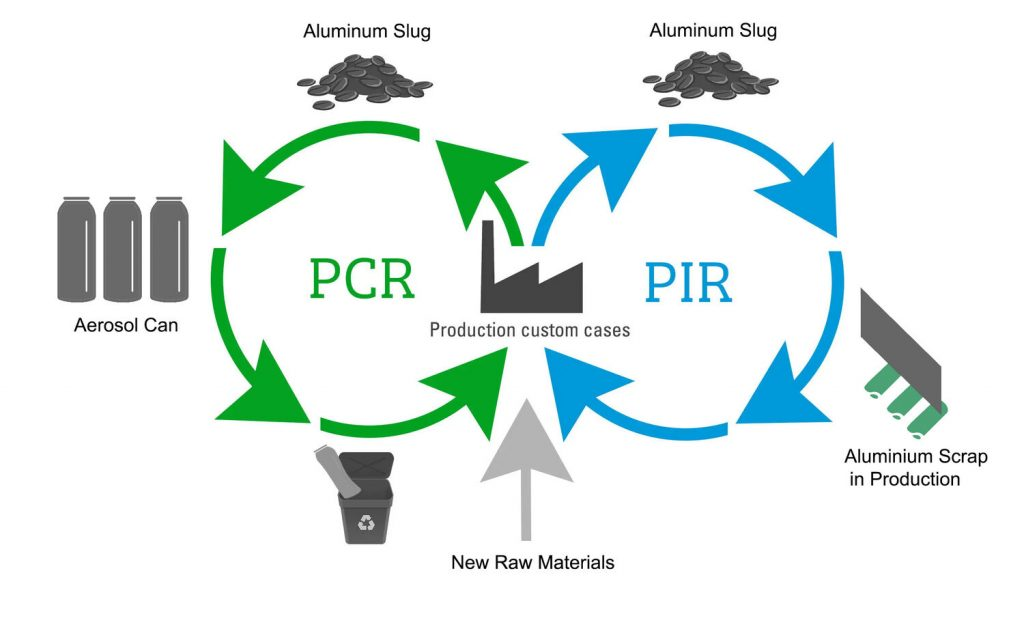

Sustainability Credentials: The company claims this new process, combined with 100% recycled and recyclable aluminum cans, cuts the carbon footprint of its flagship aerosol air fresheners by over 60% compared to 2020 levels.

The Bigger Picture: This investment represents a shift from simply designing sustainable packaging to revolutionizing the entire manufacturing lifecycle, setting a new benchmark for production efficiency and environmental responsibility.

3. Aerosol Congress 2025 Wraps Up with Focus on Carbon Capture

At the annual Aerosol Congress in Vienna, a key theme was the integration of Carbon Capture and Utilization (CCU). Multiple presentations showcased how captured CO₂ is being transformed into raw materials for both hydrocarbon propellants and the polymers used in liner coatings.

Expert Quote: Dr. Elena Fischer, a leading researcher, stated, "We are no longer just mitigating our impact. We are actively creating a circular carbon economy for aerosols. The technology to create a can from 'air' rather than fossil fuels is now at pilot scale and shows immense promise."

Looking Ahead:

The developments of November 2025 paint a clear picture: the aerosol industry is aggressively future-proofing itself. The focus has moved beyond mere recyclability to a holistic approach encompassing climate-neutral propellants, intelligent manufacturing, and full-lifecycle digital tracking. As regulatory landscapes tighten and consumer expectations rise, these innovations ensure the aerosol format will remain a viable, responsible, and advanced packaging choice for decades to come.