Classification of Aerosol Valves

In order to meet the needs of the market and customers, the types of Aerosol Valves have gradually changed from single to diversified. Actually, it has been difficult to clearly define the types of valves because many of the structures, features, and functions of valves are referenced and overlap with one another.The details are as follows:

1.Classification by Mode of Use

①Upright Aerosol Valves (positive pressure & oblique push valves): it can be used for household goods, pesticides, automotive goods, industrial goods, personal care products

②Inverted valves: applications of hair mousse, road marking, carpet shampoo, dust mite killer

③360° Aerosol Valves (steel ball type and mallet type): steel ball valves are mainly used in aerosols in which LPG and DME are the main propellants; and mallet type valves are mainly applied in aerosols in which compressed air, nitrogen and carbon dioxide are the main propellants

2.Classification by Continuous Spray Method

①Dosing Aerosol Valves: With each press of the actuator, the aerosol can release the contents in a quantitative manner according to the design requirements.

②Continuous valve: Pressing the actuator releases the contents continuously.

③Full release valve: A single actuator will release all contents of the aerosol (mainly for indoor pesticides).

3.Classification by Basic Valve Structure

①Male valves

②Female valves

|

|

The difference between female and male valves lies in the structure of the stem, female valve retains only half of the stem and the other half of the stem is on the actuator. The specificity of the structure makes it outstanding in the dispersion and filling speed of the product.

4.Classification by Valve Seal Cup Size

|

13/15/18/20mm aerosol valves |

| 20 mm aerosol valves |  |

|

1 inch aerosol valves |

Basic Structure of the Valve

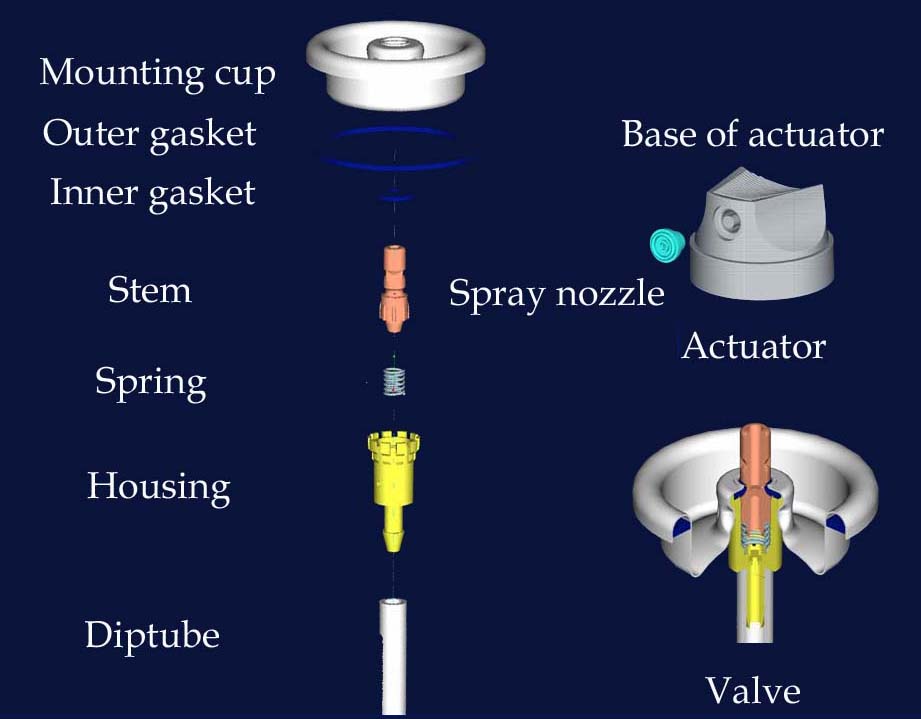

In general, the valve structure consists of actuator, insert, stem, mounting cup, spring, mounting cup gasket, stem gasket, housing, spring and dip tube.

But there are some special cases, like cost control, spraying special needs (snow, ribbon, etc.), there may be insert valves not included.

In addition, valves for inverted products such as mousse products and lighter gas will not use the dip tube. And in the current market, more and more products are using over-cap actuators instead of conventional actuators.

The Role of Valve Component

The Role of Valve Component

1.Valve Stem

The stem is the part used to connect the valve to the actuator and the size of its outer diameter affects the degree of tightness of the fit with the actuator.

2.Housing

The valve housing is the component that connects the stem, stem gasket, mounting cap, spring, and dip tube. It mainly plays a role in the aerosol valve to withstand spring force and the power of gas-liquid flow.

3.Spring

The aerosol valve spring mainly restores the valve stem to the sealed position. Obviously, the spring must have a certain strength and rigidity, and the spring wire is required to be stainless steel, otherwise it cannot withstand the erosion of the contents and use requirements.

4.Stem Gasket

The stem gasket is a critical component of the aerosol valve, and its role is to maintain a good air-tightness in the spray, effectively preventing leakage of the contents of the aerosol can. The seal of the stem gasket includes a static seal when the product is placed in a static position and a dynamic seal when the product is used. There are three main materials of stem gasket: sodium buna, nitrile rubber and butyl rubber.

5.Mounting Cup Gasket

Classification: glued; cut; set; and laminated. Main roles:

a) The mounting cup gasket is also called outer gasket. It mainly plays a good static sealing role between the aerosol valve and the aerosol can lid, so that the aerosol is stored for a long time in different environments and temperatures without producing a lot of leakage and loss.

b) Act as a buffer in the sealing process. The laminate type outer gasket can separate the mounting cup from the contents, thus ensuring that the mounting cup is not corroded.

6.Mounting Cup

The mounting cup is the base of the aerosol valve, which connects the aerosol valve to the aerosol can to seal, while the stem, stem gasket and spring are assembled by clamping the valve housing.

7.Dip Tube

The main function of the aerosol valve dip tube is to transport the liquid ejected material in the container under pressure into the valve body cavity.

8.Actuator

The actuator is an indispensable and critical part of commonly used aerosol valves.

Blogger: Miya

This article belongs to the knowledge blog, the content is selected from the website