In short, the aerosol can is a self-contained dispensing system that stores substances in a small metal aerosol canister and pushed them out in the form of fine mist, spray or foam. This mini dispensing system consists of five key components that work together to provide a consistent product.

1.Active ingredients. This is the substance that consumers want to use. In the workplace, it is usually dangerous chemicals, such as paints, pesticides, automobile sprays, adhesives and solvents.

2.Solvent. The solvent regulates the viscosity of active ingredients - it controls particle size and shortens drying time. In fact, the solvent is to ensure that the paint will not have lumpy spots, and nasal spray is not only a large wet drop. Methylal and pentoxide are commonly used solvents in aerosol cans.

3.Propellant. Propellant is a substance that pushes active ingredients out of a tank. It usually remains in a gaseous state, although it may liquefy under pressure. Aerosol foods typically use nitrous oxide or carbon dioxide as propellants, while other substances (drugs, paints, and cosmetics) use flammable hydrocarbons.

4.Can.The aerosol can is leak proof and made of aluminum or steel. They protect the ingredients from pollution and evaporation, and allow the substances inside to be pressurized.

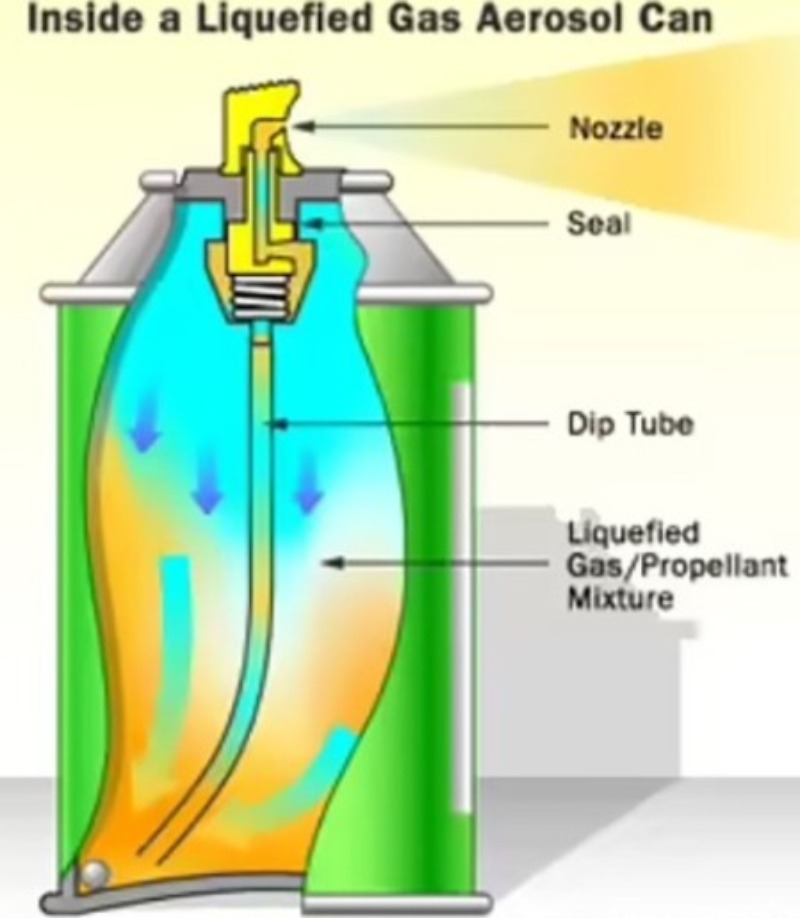

5.Aerosol valve. Most aerosol cans are activated by pressing the button on the top of the can, which opens the valve. A aerosol can valve is not a button, the valve itself is a set of (main) metal components, consisting of (usually) installation cups, inner and outer washers, springs, valve seats, and suction tubes.

|

Aerosol cans come in various shapes and sizes, accommodating various materials, but they are all based on the same basic concept: one high-pressure fluid expands, forcing another fluid through the nozzle. |

| The plastic head on the aerosol can pushes a small valve downwards, causing the pressurized content in the can to flow outward. |  |

|

There are two methods for configuring aerosol systems here. In a simpler design, you pour liquid products, seal the can, and then pump gaseous propellant through a valve system. Gas is pumped in under high pressure, so it uses a lot of force to push the liquid product downwards. You can see in the following figure how this system works. |

In this spray can, a long plastic tube extends from the bottom of the aerosol can to the valve system at the top of the can. The valve design in this picture is very simple. It has a small compressible head and a narrow passage through it. The channel extends from the entrance near the bottom of the head to the small nozzle at the top. The spring pushes the head upwards, causing the channel entrance to be blocked by a tight seal.

When you push your head down, the entrance slides under the seal, opening a passage from the inside of the jar to the outside. The high-pressure propellant gas pushes the liquid product upwards through a plastic tube and is discharged through a nozzle. Narrow nozzles are used to atomize the flowing liquid - break it down into tiny droplets to form a fine spray.