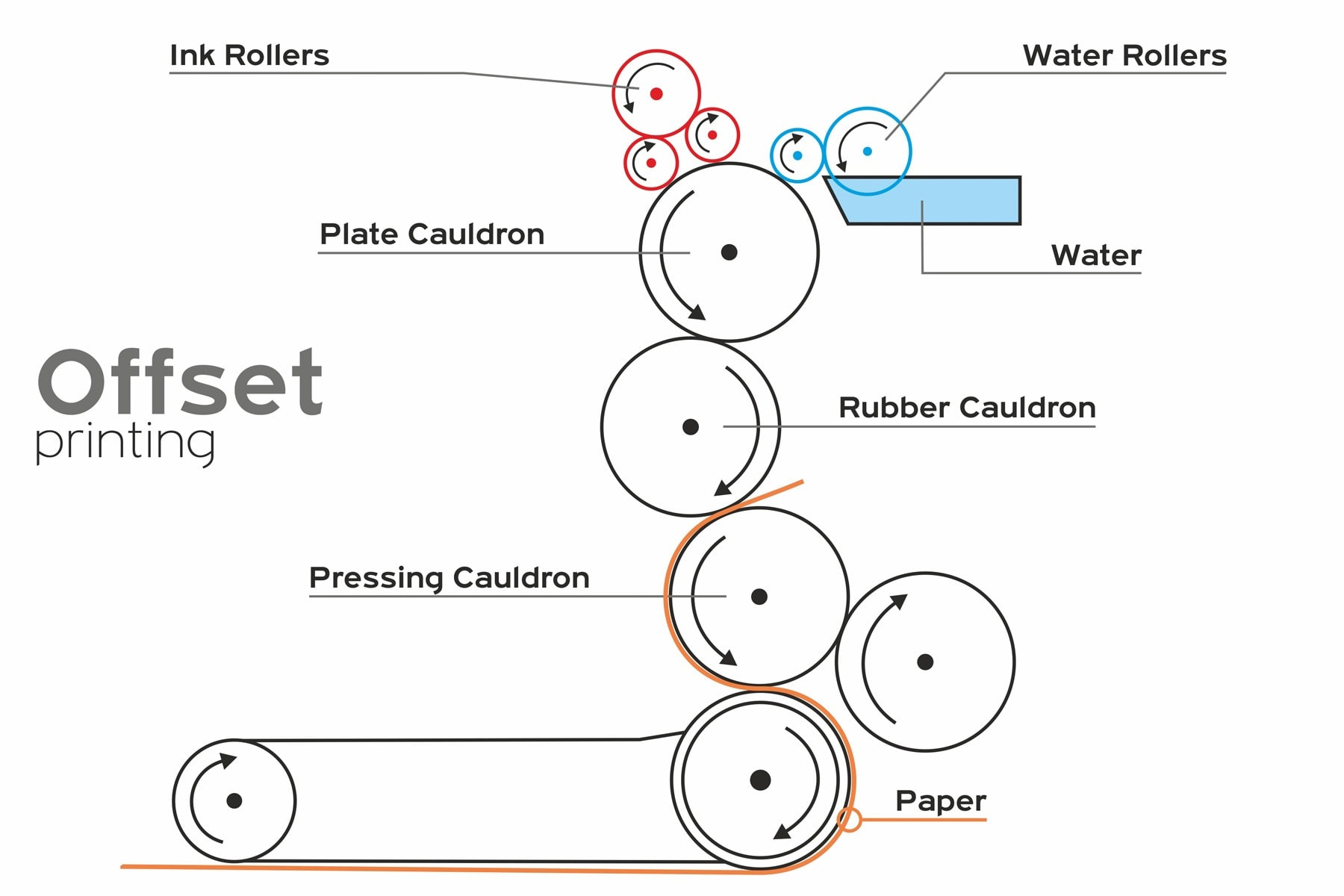

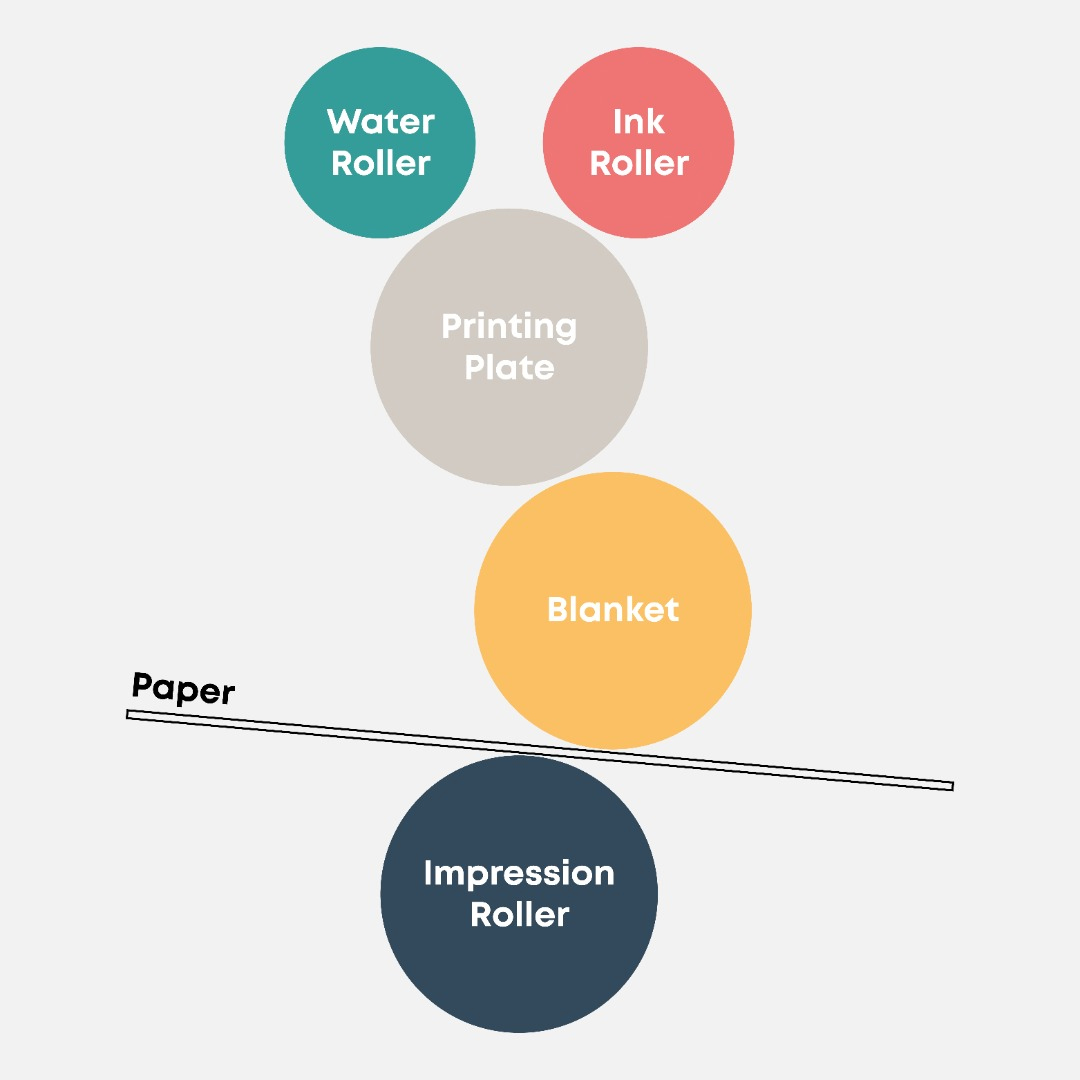

Comprehensive Overview of Printing Techniques

Click the link to get the product introduction of the 3-piece aerosol can

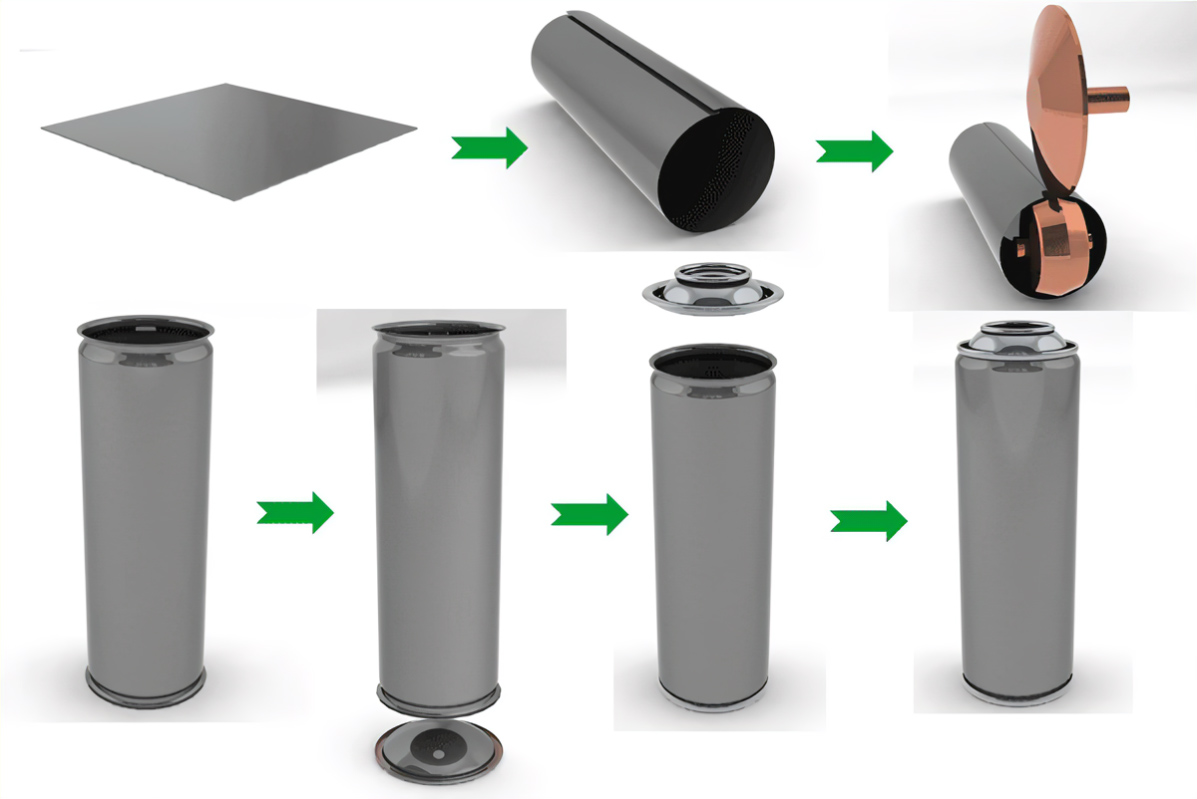

Manufacturing Flow:

Sheet printing (4-6 color process)

Varnish application (2-5μm coating)

Stoving (150-180°C for 8-12 minutes)

Bodymaking (DWI or DRD processes)

Quality Benchmarks:

Adhesion: Cross-hatch test (ASTM D3359)

Chemical resistance: MEK rubs (50+ cycles)

Sterilization: 121°C/30min steam treatment

Click the link to get the product introduction of the 2-piece aerosol can

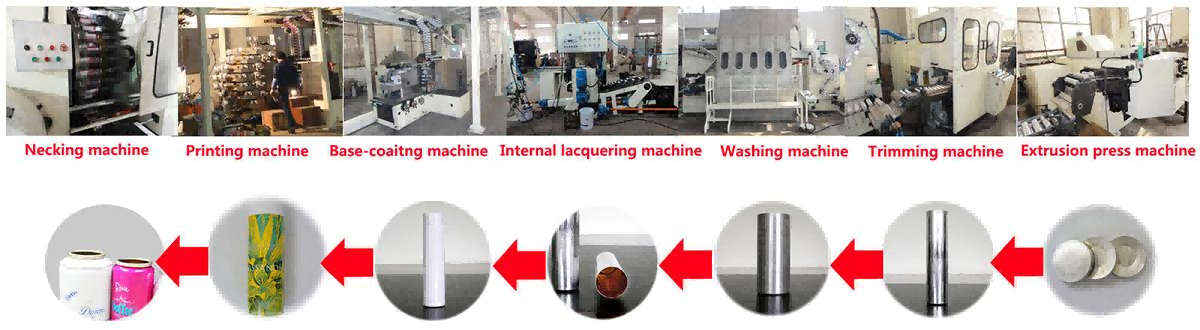

Inline Printing Systems:

Dry offset (litho) presses (6-8 stations)

UV-LED curing (365-395nm wavelength)

Hot foil stamping integration

Performance Standards:

Line speed: 800-1,200 cans/minute

Registration accuracy: ±0.1mm

Ink cure: 95%+ polymerization in <0.5s

Click the link to get the product introduction of the aluminum aerosol can

Surface Treatments:

Corona discharge (48-52 dynes/cm)

Base coat application (3-5μm)

Overprint varnish options:

Matte (20-30 gloss units)

Gloss (70-80 gloss units)

Soft-touch (special effect)

Decoration Methods:

In-mold labeling (IML)

Shrink sleeve application

Direct-to-shape digital printing